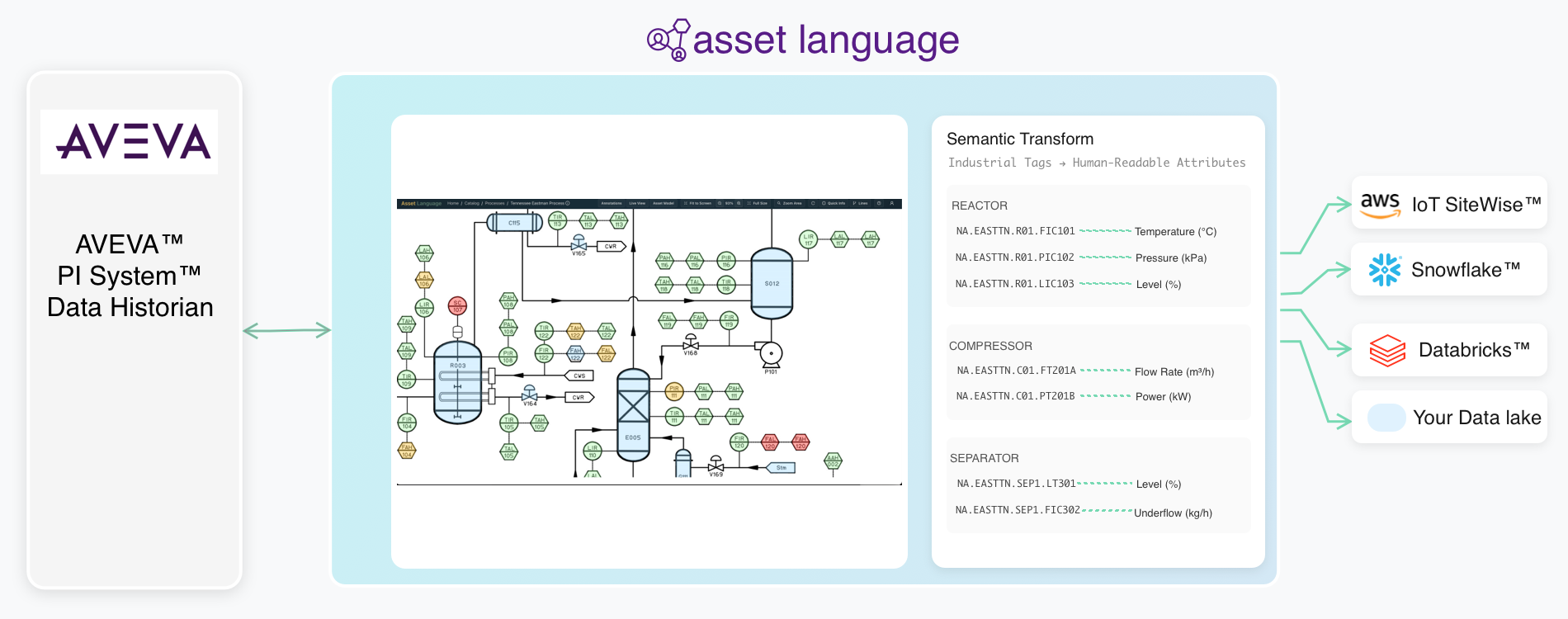

Turn manufacturing design into analytics-ready data

-

Query in Business Language: Eliminate weeks of tag decoding. Use business language like

reactor.temperatureinstead of cryptic sensor tags. -

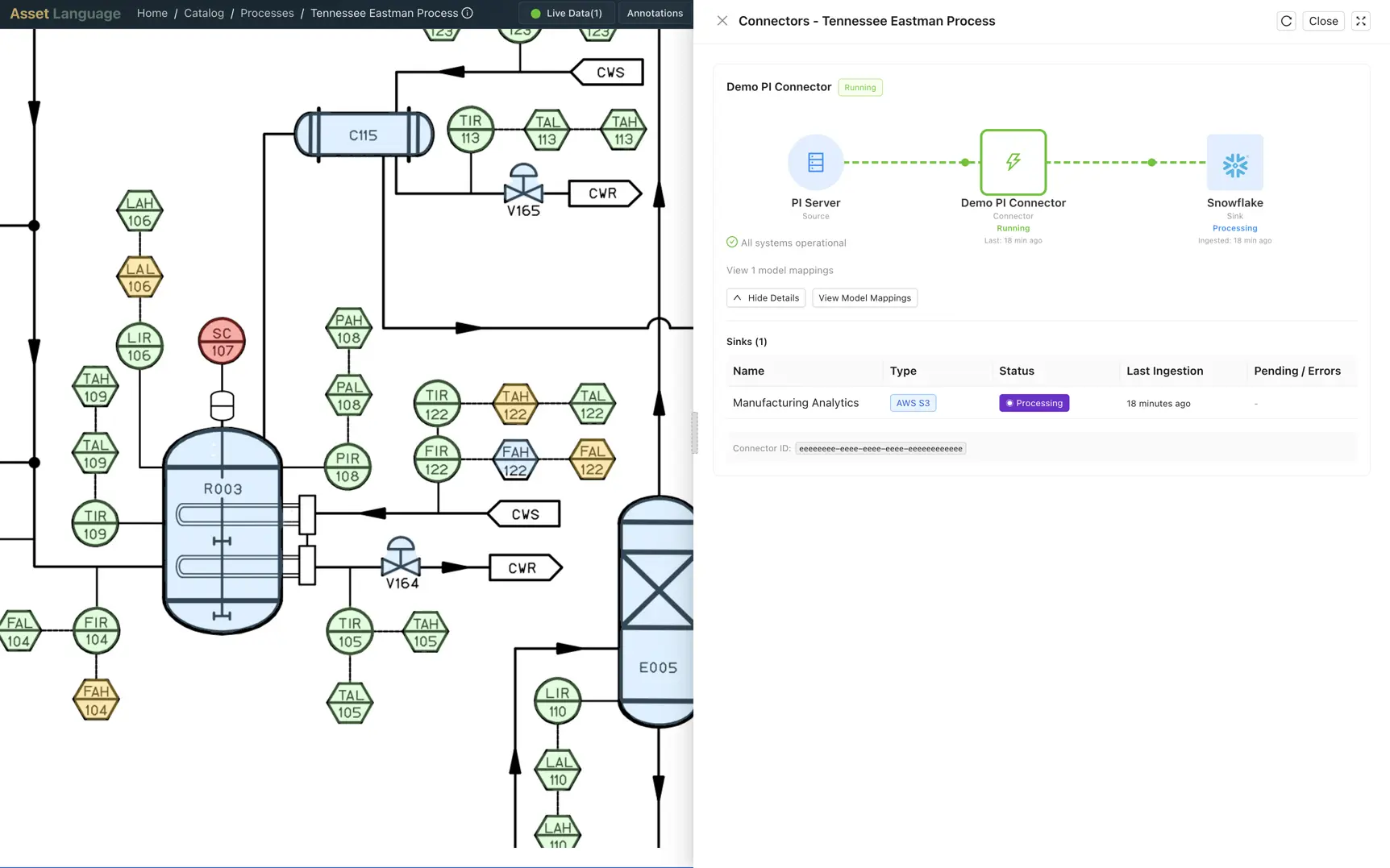

Stream to the Cloud: Deliver clean, business-ready data feeds directly to Snowflake, Databricks, and AWS IoT SiteWise.

-

Maintain Governance: Version control for P&IDs and tags keeps your data infrastructure synchronized with plant floor reality.